Shenzhen Snetop Technology Co., Ltd

"On the holly tree hang icicles high; as years pass, flowers may wither but the tree remains undaunted."

Company corporate culture:

virtue, wisdom, sincerity, perfection

Detail Information

Main Market:

North America

, South America

, Western Europe

, Eastern Europe

, Eastern Asia

, Southeast Asia

, Middle East

, Africa

, Oceania

, Worldwide

Business Type:

Manufacturer

, Agent

, Exporter

, Trading Company

, Seller

No. of Employees:

100~200

Annual Sales:

1000000-31640000

Detail Description

About Snetop

Founded in 2023, Snetop is a Shenzhen-based LED lighting manufacturer and solution provider with a robust R&D team and modern production facility. We specialize in high-quality LED lighting products — from RGBIC light strips and indoor/outdoor LED fixtures to flexible LED displays — serving global partners and project clients.

With strict quality control, advanced automation, and customer-centric service, we deliver reliable lighting solutions built for performance and durability. Whether you’re a distributor, OEM partner, or project designer, we support your needs from concept to delivery.

Our Commitment:

➡ Sustainable and efficient lighting

➡ Global standards compliance

➡ Flexible customization and support

production line

Raw Material Checking:

For the material test, it from the moment when they are arrived at our factory. The first test process is incoming quality control, that is to say IQC. Our factory colleague will test and confirm if the raw material meet all parameter , if not, they will be returned directly. Only when the test result is good, these material will be enter our warehouse to be listed.

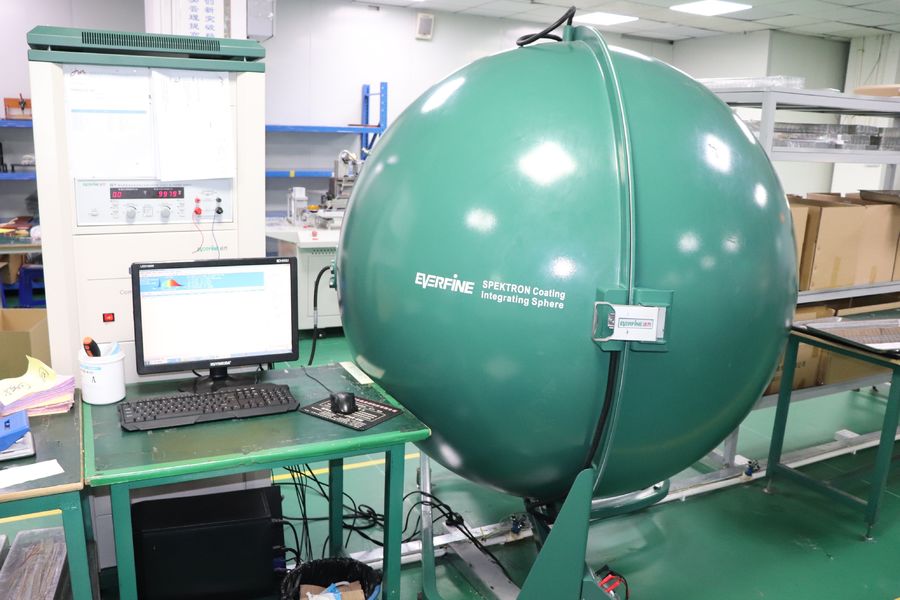

Optical checking for the LED component:

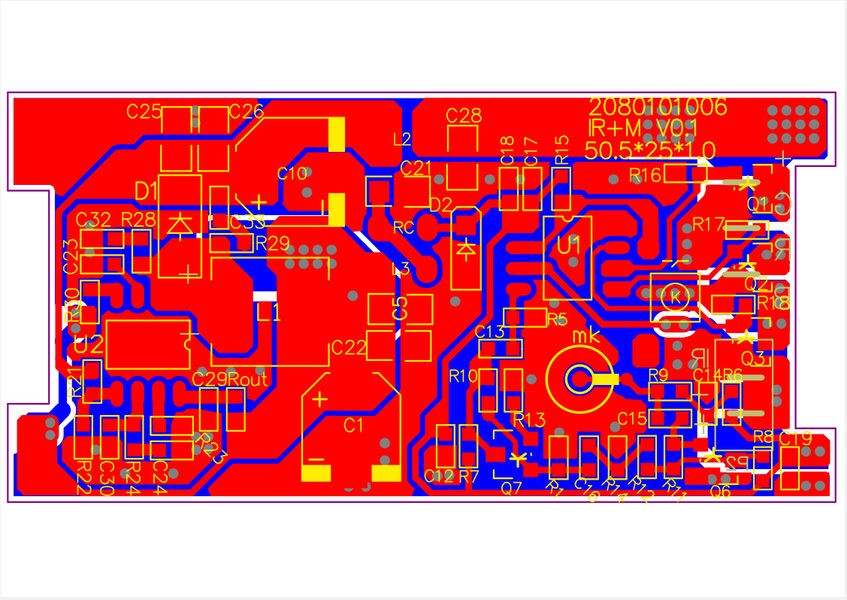

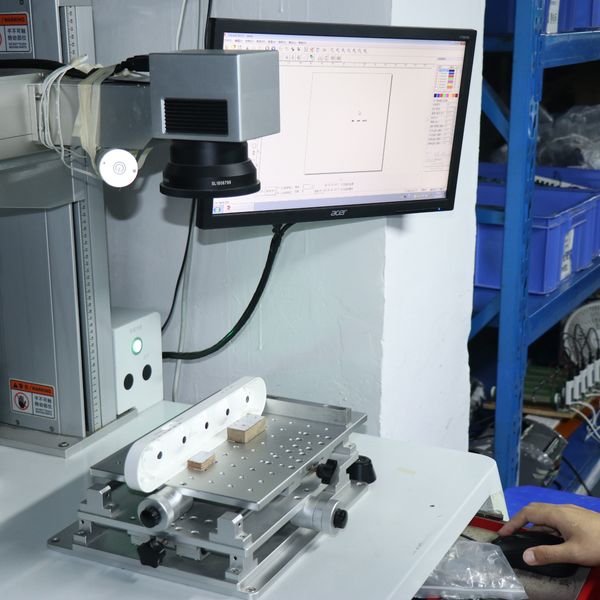

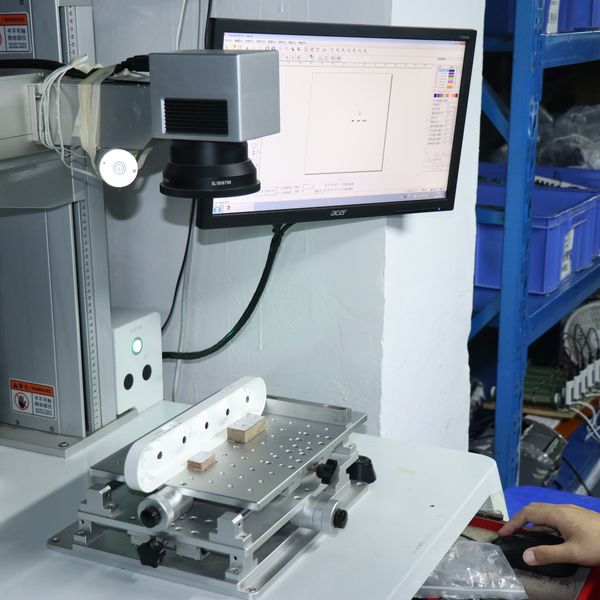

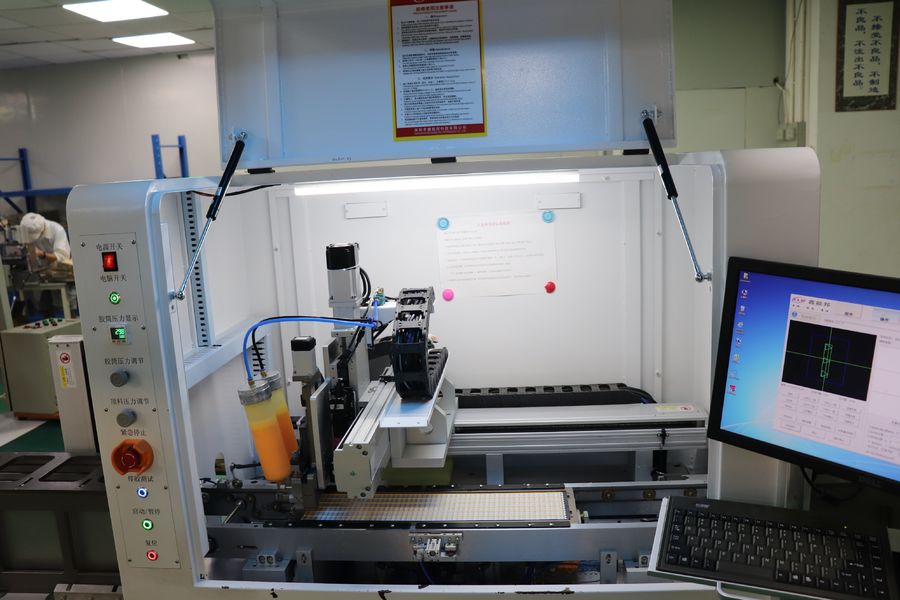

Soldering

SMT line

Testing

Extrusion

Assembly line

Aging test

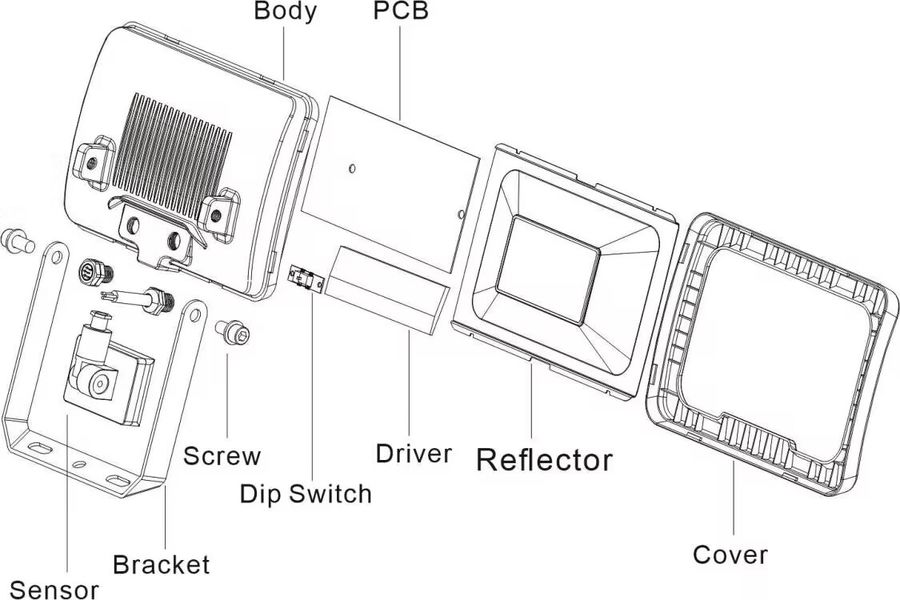

oem/odm

OEM&ODM SERVUCES

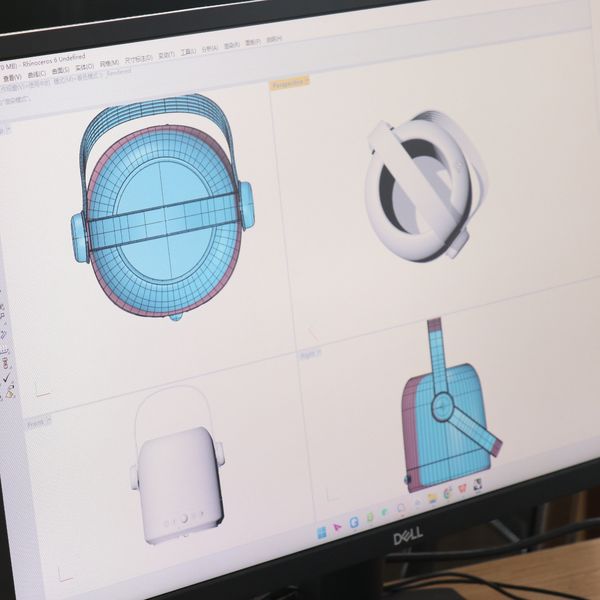

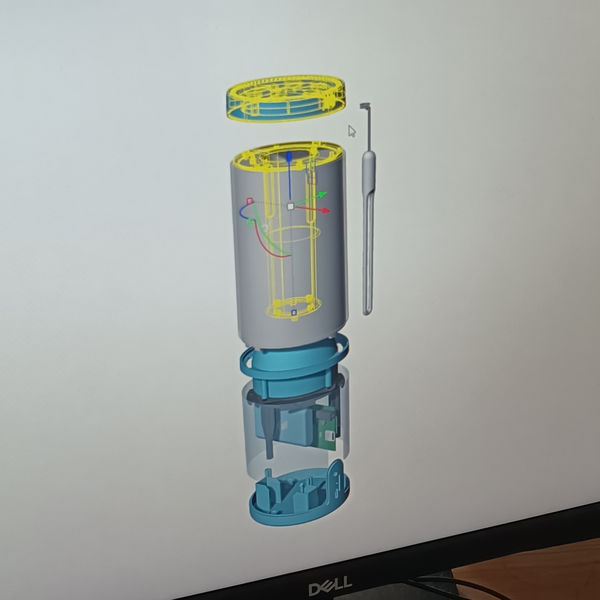

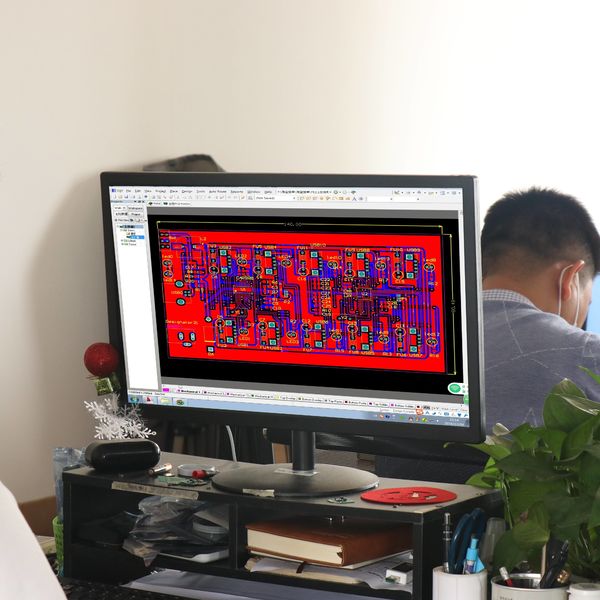

Our company has a professional design team, including electronic engineers, structural engineers, and project engineers. Each engineer has more than 10 years of rich work experience in the LED industry. According to the customer's project, product requirements, target price, tailor-made products for customers, and provide professional opinions and suggestions for customers' projects.

We provide not only products, but also professional services.

The company can provide customers with different services of OEM&ODM.

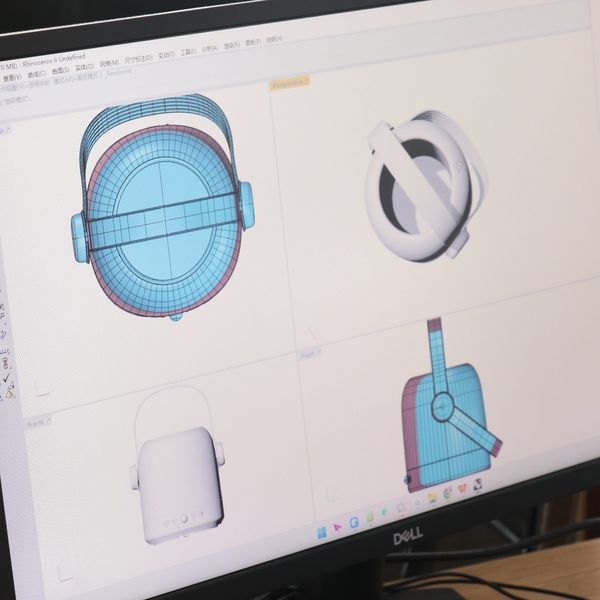

R&D

Our dedicated team works tirelessly to develop new products and improve existing ones, ensuring that we stay ahead in the market. By investing in R&D, we aim to deliver groundbreaking solutions that meet the evolving needs of our customers and drive future growth.